At JC Navalips, our Technology Department plays a crucial role in driving innovation and ensuring precision throughout our manufacturing process. Comprised of a team of highly skilled engineers and technical experts, our capabilities combine expertise with cutting-edge tools to transform concepts into high-quality products.

One of the primary tasks of our Technology Department is to analyze the documentation received from our clients. This includes carefully reviewing the specifications and requirements to gain a deep understanding of the project’s objectives.

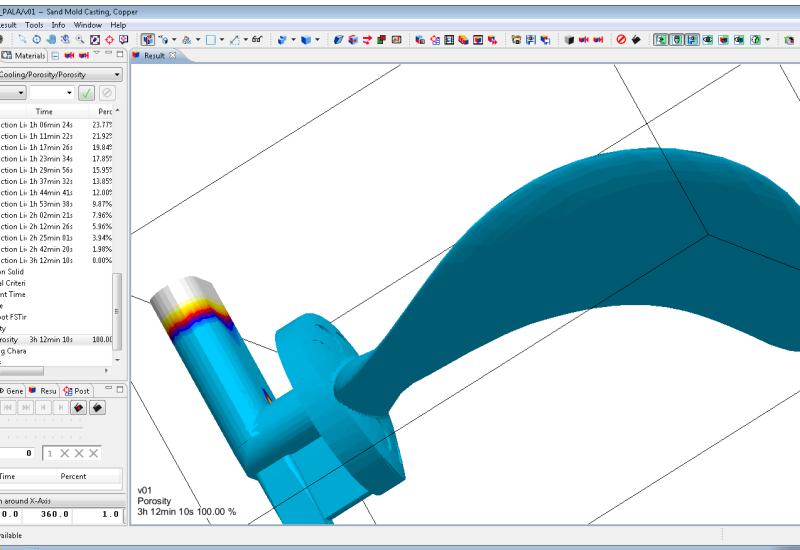

Using advanced software, our engineers create detailed 3D models of the components. These models serve as the foundation for developing casting patterns, which are essential to produce the moulds used in the casting process. By leveraging the power of simulation and digital design, we can visualize and refine the components and patterns, optimizing their performance and functionality to ensure the quality of our foundry.

3D casting simulation software

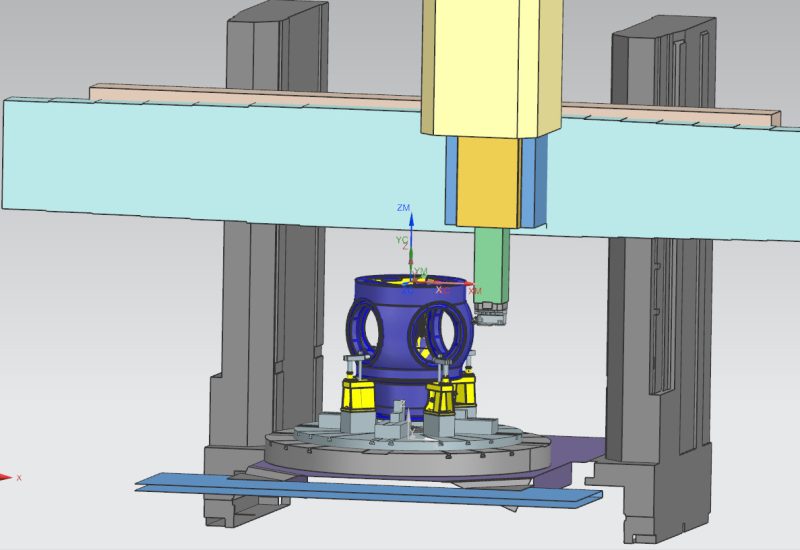

Machining simulation software

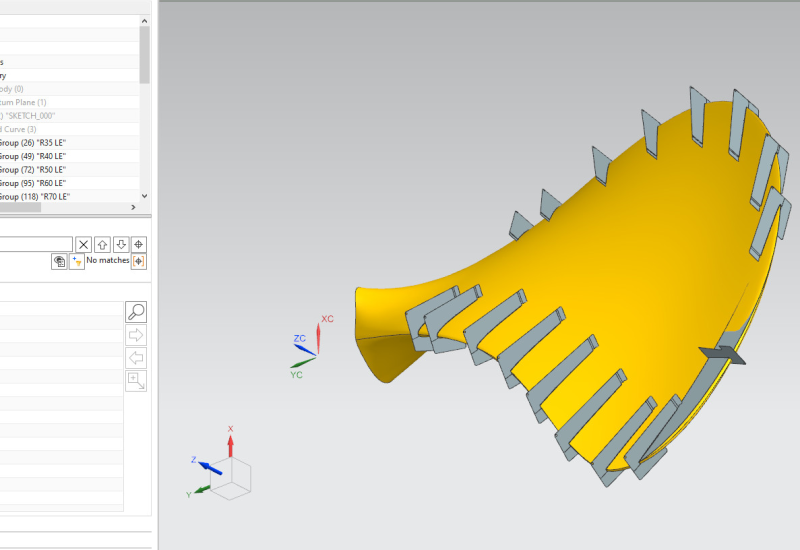

In addition, our Technology Department designs and creates all the control process across the manufacturing of our products. Through systematic attention to the details, we enhance the quality, efficiency and reliability of our products.

To accurately represent the final product, our Technology department produces an EPS (Expanded Polystyrene) model. This physical model aids during the manufacturing process, allowing us to validate the design and make necessary adjustments before proceeding to production.

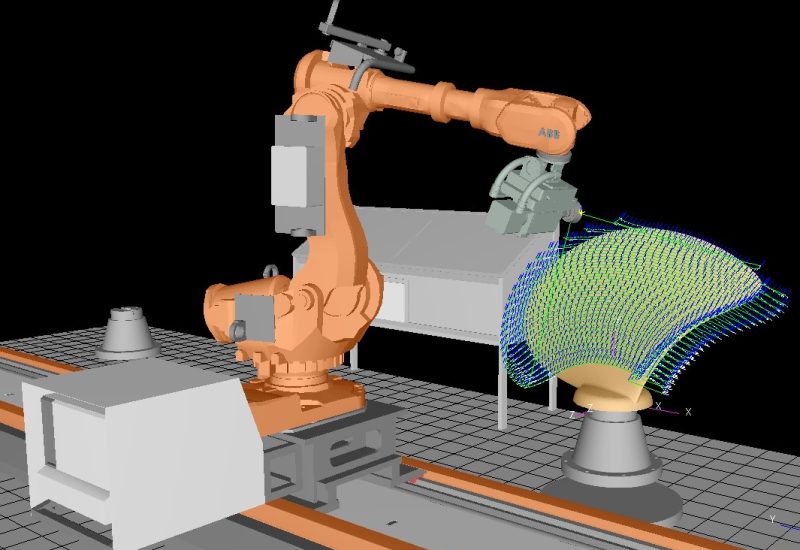

Polishing robot simulation

Finishing templates design

Furthermore, our team develops precise machining programs tailored to our state-of-the-art multi-axis machines. These programs enable us to achieve the exact specifications and tolerances required for each component. Additionally, we create comprehensive dimensional control programs that are implemented during the final stage of production. These programs verify that the components meet the required dimensional specifications, ensuring the highest level of quality.

At JC Navalips, our Technology Department is always committed to continuous improvement and staying at the forefront of technological advancements. By leveraging our expertise, cutting-edge tools, and rigorous quality control measures, we guarantee that our products consistently meet and exceed Customer expectations.

We specialize in the manufacture of propellers and components in bronze alloy for the international naval market.

Copyright © 2024. JC Navalips. Web design with ♡ by Axolot Agencia