We take pride in our meticulous engineering process, ensuring the highest quality standards.

We boast extensive expertise in casting copper alloys and crafting exceptional models.

Advanced machining capabilities to bring your designs to life with utmost precision.

Our commitment to excellence extends to the finishing stage of our blades and propellers.

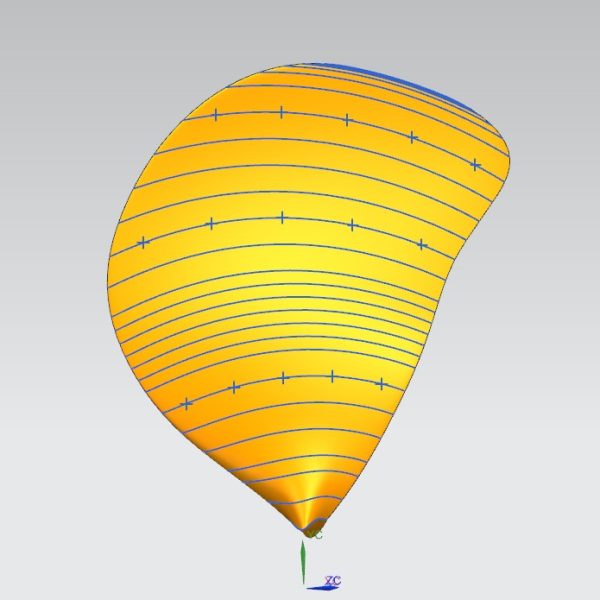

At JC Navalips, we take pride in our meticulous engineering process, ensuring the highest quality standards for every blade, propeller, and component we manufacture. Our production is supervised by our dedicated technical office, where we analyze documentation and utilize cutting-edge technology to develop 3D models for the parts, casting patterns, and machining programs. This comprehensive approach allows us to deliver finely crafted, dimensionally controlled, and careful polished finished pieces.

Our skilled team of engineers possesses a deep understanding of naval propulsion systems, enabling them to optimize the design and performance of our products. By leveraging advanced design software, we can accurately simulate and analyze various operating conditions, ensuring that our blades and propellers deliver optimal efficiency and reliability.

By combining technical expertise with state-of-the-art tools and a commitment to precision, we guarantee that every piece manufactured at JC Navalips undergoes rigorous quality control processes. Our engineering excellence sets us apart, allowing us to deliver products that exceed expectations and propel vessels with utmost efficiency and performance.

At JC Navalips, we boast extensive expertise in casting copper alloys and crafting exceptional models for the production process. Our proficiency in mold-making and sand-casting techniques allows us to create intricately designed molds and achieve precise casting of each component. We take great pride in our ability to deliver top-quality castings that meet the highest industry standards.

In our casting process, we employ a meticulous approach to ensure optimal physical and chemical properties for each material. With every pour, we conduct thorough chemical analyses and perform degassing techniques to guarantee the desired characteristics of the casted parts. This attention to detail enables us to consistently deliver components that possess exceptional strength, durability, and corrosion resistance.

Our team of skilled craftsmen is dedicated to creating intricate molds that capture the finest details of each design. From pattern production to mold assembly, we employ advanced techniques to ensure precise reproduction of the intended shape and dimensions. This precision craftsmanship translates into superior performance and reliability in the final products.

With a commitment to continuous improvement, we stay updated with the latest advancements in casting technology and techniques. Our state-of-the-art facilities and equipment allow us to optimize the casting process, ensuring efficient production while maintaining the highest level of quality.

When you choose JC Navalips for your casting needs, you can trust that our team will deliver unparalleled expertise and craftsmanship. We take pride in our ability to transform raw materials into finely crafted components that meet and exceed your expectations.

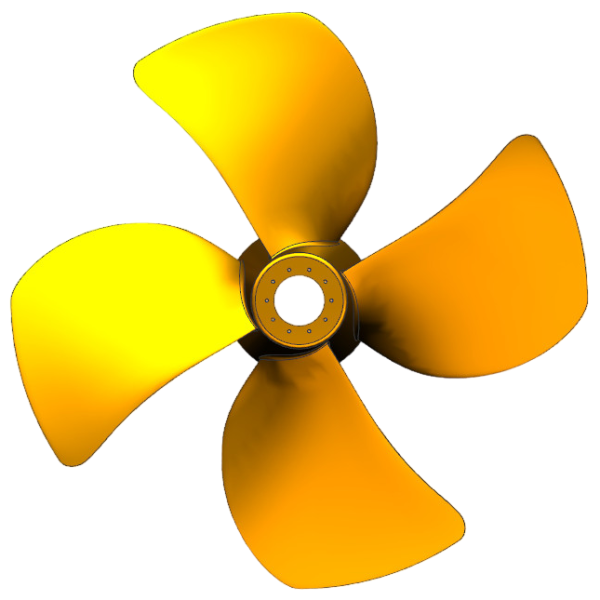

At JC Navalips, we possess advanced machining capabilities, including milling machine and lathe, to bring your designs to life with utmost precision. Our skilled machinists utilize these cutting-edge tools to machine components according to the specifications outlined in the engineering drawings.

Our state-of-the-art machines allow us to precisely shape and refine the components, ensuring that they meet the required tolerances and specifications. With our expertise and attention to detail, we deliver components that seamlessly integrate into your vessel’s propulsion system, guaranteeing superior functionality and performance.

At JC Navalips, we understand the critical role that precision machining plays in achieving optimal performance and reliability. Our skilled machinists work diligently to ensure that every piece is carefully machined, delivering the highest standards of quality and a perfect fit.

We are committed to exceeding customer expectations and maintaining the highest level of satisfaction. With efficient machining processes and stringent quality control measures, we ensure that your components are delivered on time and in accordance with your exact requirements.

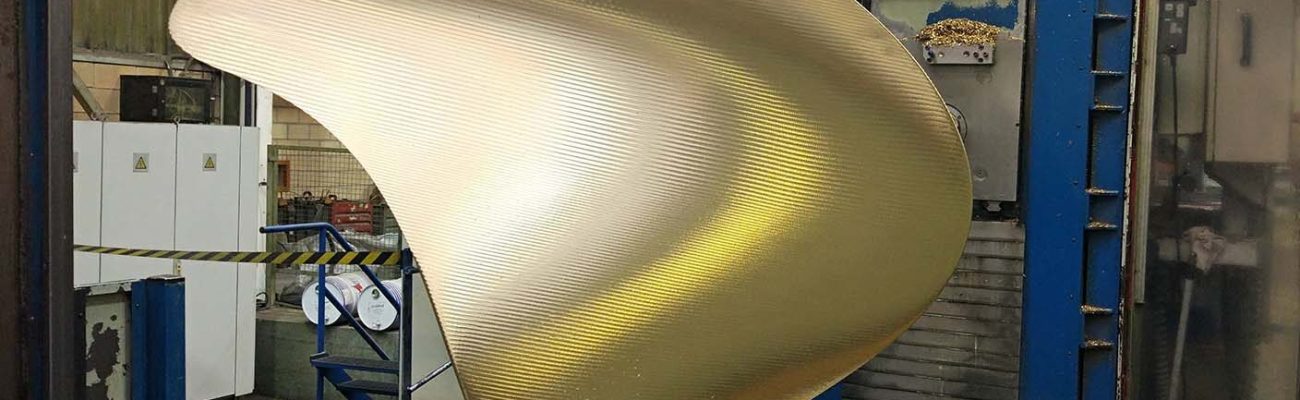

At JC Navalips, our commitment to excellence extends to the finishing stage of our blades and propellers. We understand that the final touches are crucial to ensure optimal performance and efficiency. That’s why we dedicate a specialized team to the meticulous grinding and polishing of the blades, guaranteeing the precise geometric specifications necessary for the ultimate performance of our products.

Our skilled technicians employ advanced techniques to accurately shape and refine each blade. With utmost precision, they remove any imperfections and fine-tune the geometrical parameters, ensuring that the finished blades meet and exceed the required performance standards. Through careful polishing, we achieve smooth surfaces that minimize friction and maximize propulsion efficiency.

We understand the importance of dimensional accuracy in achieving optimal hydrodynamic performance. Our rigorous quality control measures ensure that each blade is thoroughly inspected to meet the stringent specifications outlined in the design. This attention to detail guarantees that our blades and propellers deliver exceptional performance, reducing fuel consumption and enhancing maneuverability.

At JC Navalips, we take pride in our ability to deliver blades and propellers that surpass expectations. Our commitment to finishing excellence ensures that your vessel benefits from the highest level of performance and efficiency.

Discover all our products

Repair of naval components